| |

|

| |

| |

ADD: No12,Xuejian Road,Xueyan Town,Changzhou,Jiangsu,China |

| |

P.C.: 213169 |

| |

Tel:+86-519-81190160 |

| |

Fax:+86-519-81190162 |

| |

E-mail:market@taileike.com |

| |

URL:pssstw.cn |

|

|

| |

CT-C Series Hot Air Circulating Drying Oven CT-C Series Hot Air Circulating Drying Oven

>> Descriptions

CT-C series hot air circulation oven adopts noise elimination and thermal stable axial flow fan and automatic temperature control system. The entire circulation system is enclosed to make that the heat efficiency of the drying oven increases from 3-7% of the

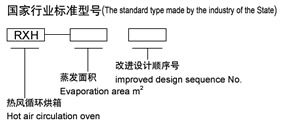

traditional drying oven to 35-40% of the present one. The highest heat efficiency can be up to 50%. The successful design of CT-C hot air circulation oven makes that the hot air circulation drying oven in our country reach the advanced level in the world. It savesenergy and increases the economic benefit. In 1990, the medical management bureau of the State issued the industry standard and the uniform type is RXH.

>> Applications

This drying oven is suitable for material and product hot solidification and dry de-watering in the pharmaceutical, chemical, food, farming, side-product,aquatic product, light industries, heavy industries and othersindustries. Such as: raw material medicine, crude drug,preparedherbalmedicine ofChinese traditional medicine,plaster,powder,particle, drinking agent, pill, packingbottle,pigment,dyestuff, de-watering vegetable, dried fruit piece, sausage, plastics, resin, electric component, baking varnish and etc.

>> Explanation

1.Options of heat source: steam, electricity, or far infrared, or both steam electricity.

2.Drying temperature: steam heating 50-130癈, Max.140癈.

3.Electricity and far infrared:50-300癈.Automatic control system and computer control system on request.

4.Commonly using steam pressure 0.2-0.8Mpa(2-8 bar).

5.For CT-C-I, electric heated, rated power consumption:15Kw, real consumption : 5-8Kw.

6.The special requirements should be indicated at the time of order.

7.For operation temperature of over 140癈 or less than 60癈, please indicate when order.

8.The ovens and baking trays made by our factory are uniform in dimensions, and can be exchanged each other.

9.Baking plate dimensions:460x640x45mm.

Technical parameters:

Spec. of industry standard |

specification |

batch drying capacity

(kg) |

power(kw) |

steam to be consumed

(kg/h) |

Heat exchange area

(m2) |

Velocity

(m3/h) |

temperature different of the top and the bottom |

Baking trays |

Overall dimensions

(LxWxH)mm |

baking cart to be used(set) |

| RXH-5-C |

CT-C-0 |

25 |

5 |

5 |

5 |

3400 |

±2 |

8 |

1400×1200×1600 |

0 |

| RXH-14-C |

CT-C-IA |

50 |

0.45 |

10 |

10 |

3400 |

±2 |

24 |

1400×1200×2000 |

1 |

| RXH-14-C |

CT-C-I |

100 |

0.45 |

18 |

20 |

3450 |

±2 |

48 |

2300×1200×2000 |

2 |

| RXH-27-C |

CT-C-Ⅱ |

200 |

0.9 |

36 |

40 |

6900 |

±2 |

96 |

2300×2200×2000 |

4 |

| RXH-41-C |

CT-C-Ⅲ |

300 |

1.35 |

54 |

80 |

10350 |

±2 |

144 |

2300×3220×2000 |

6 |

| RXH-54-C |

CT-C-Ⅳ |

400 |

1.8 |

72 |

100 |

13800 |

±2 |

192 |

4450×2200×2000 |

8 |

| RXH-25-A |

High efficiency and high temperature far infrared sterilizing oven |

1200×1000×1600 |

1 |

|

|

|